TUMCS | Thomas Höfer | 01.04.2022

Prof. Nicolas Plumeré

Image: Jan Winter / TUM

The decarbonisation of our economy will need a transition from fossil fuels to renewable alternatives such as green hydrogen in a large number of industrially essential processes. The main obstacle to this industry-wide conversion is the cost-effective availability of sustainably produced hydrogen, which needs to economically compete with hydrogen produced from fossil-based natural gas. One of the bottlenecks for the large-scale and economically viable production of hydrogen from renewable energies is the need for precious metals such as platinum as catalysts. It is therefore essential that platinum is replaced by freely available and cheaper alternatives without sacrificing efficiency. Fortunately, nature shows us with its multitude of biological catalysts, the enzymes, how efficient catalysts can be produced from widely available earth abundant materials. In fact, Nature has already evolved hydrogenases, a class of biocatalysts that is capable of producing hydrogen from water or splitting hydrogen. However, the hydrogenases known today are adapted to the physiological conditions within the various organisms in which they occur and not to the harsh conditions of fuel cells and electrolysers. Natural enzymes must therefore be modified to withstand these conditions in order to gain broad industrial relevance.

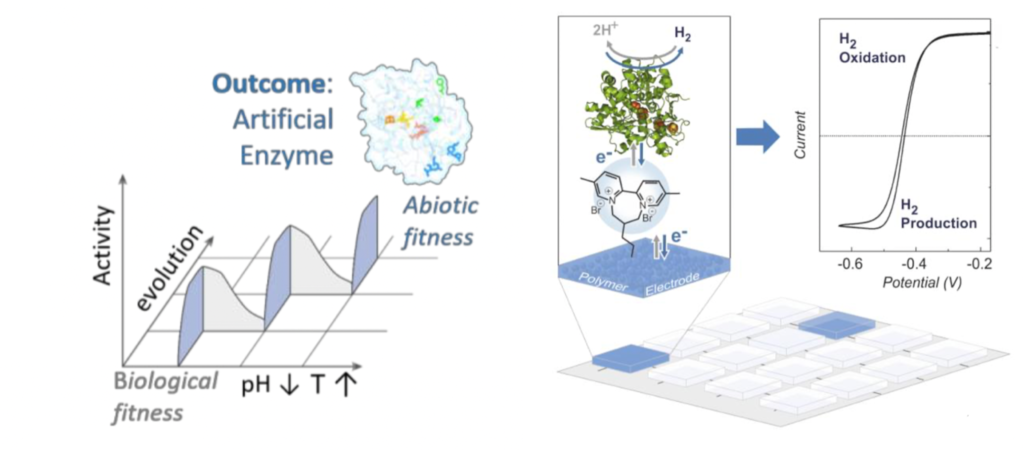

Left: Evolution of an artificial Enzyme to increase survivability at higher temperatures and lower pH-values. Right: Schematic of an electrode array with artificial hydrogenases for the high-throughput method. Image: Prof. Nicolas Plumeré / TUM

Today’s biotechnology is capable of modifying enzymes by exchanging amino acids, but these approaches are mostly limited to natural amino acids. With his ERC Consolidator project “E-VOLUTION”, Prof. Plumeré wants to break through this barrier and develop a platform, in which artificial enzymes that survive the extreme conditions of industrial processes, can be produced automatically. Beyond hydrogenases, this method will enable the development of various, highly active, and tailor-made enzymes for a wide range of chemical reactions and thus will accompany the chemical industry on its way towards sustainability.